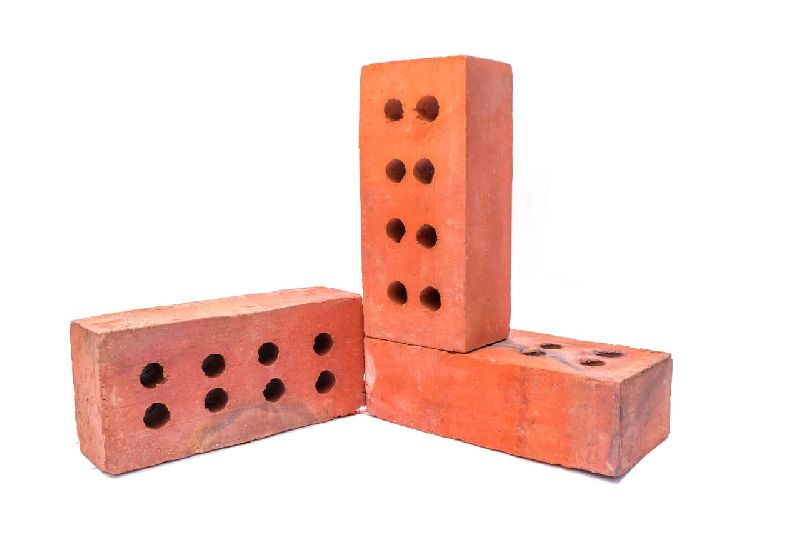

Are you in the market for high-quality 8 hole Perforated bricks? Look no further! We have scoured the industry and compiled a list of top manufacturers known for producing exceptional products. Whether you’re an architect, contractor or simply a DIY enthusiast, these companies offer unparalleled craftsmanship and durability to meet your needs. Join us as we explore the best names in this niche market and discover why they are leaders in their field.

Benefits of Using 8 Hole Perforated Bricks

There are numerous benefits of using 8 hole perforated bricks in construction projects. Some of the key advantages include:

- Enhanced drainage – The holes in the bricks allow for enhanced drainage, which is beneficial in areas with high rainfall or where there is a risk of flooding.

- Improved air circulation – The holes also improve air circulation, which helps to keep buildings cooler in hot weather and reduces the risk of condensation and damp problems.

- Reduced weight – 8 hole perforated bricks are typically lighter than solid bricks, making them easier to transport and handle on construction sites.

- Enhanced acoustic properties – The porous nature of the bricks helps to absorb sound, making them an ideal choice for use in walls separating noisy areas from quieter ones.

- Versatile design – Perforated bricks can be used in a variety of applications and are available in a range of colors and finishes to suit any project requirements.

Quality Control for 8 Hole Perforated Bricks

There are numerous benefits to using hole perforated bricks in construction, including improved drainage and ventilation, as well as a more aesthetically pleasing finished product. However, as with any building material, it is important to ensure that the bricks you select meet the highest standards of quality control.

Here are eight things to look for when assessing the quality control of hole perforated bricks:

- Check that the bricks are properly kiln-dried. This will help to prevent shrinkage and cracking during use.

- Inspect the bricks for any defects, such as cracks or chips. Defective bricks should be discarded.

- Make sure that the holes in the bricks are of uniform size and spacing. This ensures proper drainage and ventilation.

- Ensure that the edges of the bricks are smooth and even. Rough edges can cause problems during construction.

- Make sure that the surface of the bricks is clean and free of debris. This helps to prevent staining and provides a better foundation for mortar adhesion.

- Check that each brick is stamped with the manufacturer’s logo or name. This helps to identify counterfeit products.

- Request samples of the bricks from the manufacturer before placing an order . This allows you to assess the quality for yourself before making a large purchase .

- Finally , always buy from a reputable supplier who has a good track record of providing high-quality products .

Conclusion

There is no shortage of machine made 8 hole bricks manufacturers that offer top-notch products, but it is important to make sure you are getting the best possible product for your application. We hope our comprehensive list of the top 8 hole perforated brick manufacturers has helped you find a company that meets both your budget and quality requirements. With these tips in mind, we wish you luck with finding the perfect manufacturer for your project!