When you’re dealing with medical equipment, accuracy and safety aren’t just important—they’re everything. If you’ve ever wondered what goes into making sure that syringes, IV lines, and similar tools fit together securely, the answer might surprise you. One critical piece of the puzzle is the ISO594 Luer gauge. But what exactly is it? Why does it matter? And how does something like an Environmental Test Chamber tie into all of this?

Let’s break it down in a simple, friendly way—just like you’re having coffee with a curious friend who happens to work in medical manufacturing.

What Is the ISO594 Luer Gauge, and Why Should You Care?

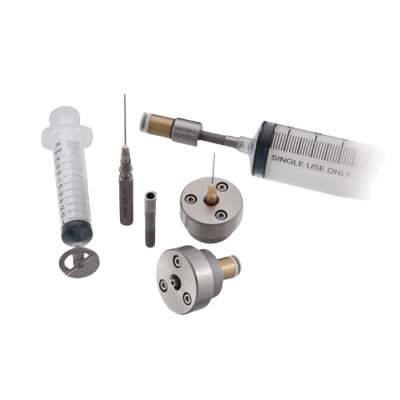

The term ISO594 Luer gauge might sound complicated, but it’s actually pretty straightforward once you understand its role. ISO594 is an international standard that defines how Luer connectors (those twist-on or push-fit tips you find on syringes and IV tubing) should be designed and tested.

The “Luer” part refers to the small, tapered fittings that allow medical devices to connect with one another.

The “gauge” part tells us about the dimensions and tolerances of these connections.

“ISO594” is the actual standard document that manufacturers follow to ensure these connections are safe, tight, and leak-free.

Imagine trying to use a charger that doesn’t quite fit your phone—it’s frustrating, maybe even dangerous. Now imagine that same issue in a hospital where fluid needs to flow precisely from an IV bag into a patient’s vein. That’s why ISO594 Luer gauge compliance is so essential.

How Are These Gauges Tested for Safety?

This is where the Environmental Test Chamber enters the scene. Think of this chamber as a controlled testing environment—a super-smart oven or freezer that can simulate extreme conditions.

Medical devices, especially those with Luer fittings, must remain reliable in different temperatures, humidities, and pressures. An Environmental Test Chamber helps engineers test whether Luer connections maintain their shape and performance in:

Cold storage conditions (think about a hospital fridge)

High-heat scenarios (like during sterilization)

High-humidity environments (similar to tropical climates)

By using the ISO594 Luer gauge inside an Environmental Test Chamber, manufacturers can confirm that the product remains leak-proof, durable, and functional, even when the environment changes.

Where Is the ISO594 Luer Gauge Used?

Anywhere that small fluid connectors are used in the medical world, you’re likely to find components tested with the ISO594 Luer gauge.

Hospitals and clinics rely on it for syringes, catheters, IV systems, and more.

Laboratories use Luer fittings for precise sample transfers.

Home care kits often include syringes with Luer tips for easy medication administration.

Whether you’re a nurse inserting an IV or a parent giving medication through a feeding tube, you’re depending on that Luer connection to do its job right. That’s why rigorous testing and design—backed by tools like the ISO594 Luer gauge and the Environmental Test Chamber—is so important.

What Should Manufacturers Keep in Mind?

For those in the medical manufacturing world (or those just curious), there are a few key takeaways:

Stay compliant: Always follow the ISO594 standard when designing Luer components. It’s not just about safety—it’s also about compatibility with other devices worldwide.

Test under real-world conditions: Use an Environmental Test Chamber to simulate the extremes. If a device can survive a worst-case scenario in the lab, it’s more likely to perform well in the real world.

Think long-term: Durability matters. Patients and healthcare providers need products that don’t fail when it matters most.

Tips for Choosing the Right Testing Equipment

If you’re in the business of designing or testing Luer components, choosing the right equipment is essential.

-

Look for Environmental Test Chambers that can mimic a broad range of conditions—from icy cold to high humidity and heat.

-

Make sure the chamber is compatible with small, sensitive devices like syringes or tubing connectors.

-

Choose chambers with precise controls and reliable data logging so you can track how your product performs over time.

And don’t forget—the ISO594 Luer gauge itself must be certified and accurate. It’s the benchmark for your testing, so quality there is non-negotiable.

Final Thoughts: Why It All Matters

In a world where every detail in healthcare can make a difference, standards like ISO594 Luer gauge help ensure that devices work as intended. And with the help of tools like the Environmental Test Chamber, manufacturers can confidently deliver safe, consistent, and high-quality medical products.

So the next time you see a syringe or IV tube, remember—behind that simple connection is a whole world of science, engineering, and testing designed to protect lives.