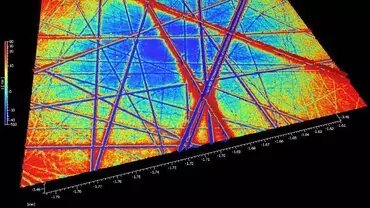

Surface flatness is important in many industries, as it affects the performance and function of a product. Surface flatness measurement is the process of evaluating the flatness of a surface. This is typically done using a surface profilometer, which is a device that measures the topography of a surface by moving a probe across the surface and measuring the distance between the probe and the surface at different points. For example, in the automotive industry, it is important for ensuring that car bodies and components fit together properly, while in the aerospace industry, surface texture measurement is important for ensuring that aircraft parts meet safety and performance standards. Surface flatness can be measured in units such as micrometers or nanometers, and is typically evaluated against a set of standards or tolerance limits.

Different applications for surface flatness measurement

There are many different applications for surface flatness measurement in a variety of industries, including manufacturing, engineering, construction, and quality control. Some examples of the uses of surface flatness measurement include:

- Quality control and inspection: To ensure that manufactured parts or components meet specified tolerances and dimensions, and to identify any defects or deviations from the desired specifications.

- Manufacturing and production: To ensure that machinery or equipment is properly aligned and functioning correctly, and to identify any issues that may affect the quality or efficiency of the manufacturing process.

- Construction: To verify the levelness of a construction site or foundation, and to identify any issues that may affect the stability or safety of the structure.

- Automotive and aerospace industries: To ensure that vehicle component, such as wheels or landing gear, are properly aligned and functioning correctly.

- Electronics and semiconductor manufacturing business: To ensure that electronic components, such as circuit boards or microchips, are properly aligned and functioning correctly.

- Optical and medical device manufacturing: To ensure that the surfaces of optical and medical devices, such as lenses or mirrors, are properly aligned and functioning correctly.

- Surface finish analysis: To determine the roughness or finish of a surface, and to identify any issues that may affect the quality or performance of the surface.

The use of surface texture measurement is widespread across different industries.

Surface texture measurement is used in a wide range of industries, including automotive, aerospace, manufacturing, medical device, and consumer products. In these industries, surface texture measurement is often used to ensure that parts and products meet specific surface finish requirements for functional, aesthetic, or safety reasons.

The automotive industry uses this to ensure that car body panels have the correct surface finish for paint adhesion, to ensure that brake components have the correct roughness for proper braking performance, and to ensure that engine components have the correct surface finish for optimal performance and wear resistance.

The aerospace industry uses this measurement to ensure that airplane components have the correct surface finish for optimal performance, such as the smoothness of wing surfaces for reduced drag, or the roughness of bearing surfaces for proper lubrication. check more about Kohler Shower Heads

In manufacturing, the use is to ensure that machined parts have the correct surface finish for proper functioning, such as the roughness of gears for proper meshing or the smoothness of bearing surfaces for low friction.

The medical device industry uses STM to ensure that implants and other devices have the correct surface finish for optimal performance and biocompatibility.

The consumer products industry uses STM to ensure that products have the correct surface finish for aesthetic or functional purposes, such as the smoothness of smartphone screens for touch sensitivity or the roughness of grips on tools for enhanced grip.